2023-01-11 16:56:34

2022-09-06 10:34:35

2022-09-06 10:30:49

2023-02-15 10:13:32

We do not only discover problems, but solve them!

CFI oversight will save cost by reducing defective products

- Control moisture to prevent splitting

- Supervise balance time to prevent warping

- Inspect glue used for excess formaldehyde preventing

- Avoid any business reputational damage caused by recall

- Ensure proper quality at every production stage

- Estimate possible production and shipment delays

- Optimize your quality control budget

- Improve your purchase efficiency

Appearance Check

Check for avoiding coating variation, surface cracking, unfit T&G and unsmooth finish of floor.

![]()

Density Check

Insufficient material density will cause inconsistent grain appearance and possible surface cracking.

![]()

Warping Check

Board warp results in installation difficulty, creaking floor noise and possible sub-floor structure damage.

![]()

Moisture Content Test

The moisture content of floor is critical to ensure floor structure stability in changing climate/humidity. Improper moisture content will result in expansion of boards, which need major repair or floor replacement.

![]()

Film Adhesion Test

It used to confirm proper primer and top coat application. Improper surface coating will result in finish peeling and bubbles appearing on floor surface.

![]()

Wear Resistance Test

For testing finishing resistance against scratching and other surface deformation, this test is frequently applied. If floor finish wear resistance does not meet standards, scratches might appear after using a period of time.

![]()

Dip Peeling Test

It used to check adhesive bonding of laminate structures. Weak adhesive binding might result in deformation, layer, drum and other issues, that a strong adhesive binding is necessary to overcome the expansion coefficient variation.

![]()

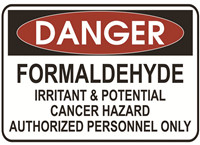

Formaldehyde Emission Test

Testing service is available to detect excess levels of formaldehyde present in floor. Formaldehyde risk will not only harm health, but greatly affect the business reputation, and cause serious losses.

![]()

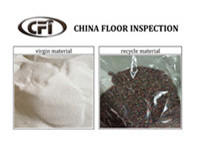

Virgin & Recycle Material Check

To verify that no recycled material is used in production process.

Recycled material may be environmental friendly, but for flooring, the use of recycled material will cause excessive swelling, layer and warping.

![]()

Tags : Avoid Flooring Problems Reduce Import Risks Professional Floor Services Floor Inspection Price Floor Shipment Problems Floor Shipment From China

Tags : Floor Inspection In China Vinyl Flooring Pre-shipment Inspection Floor Quality Control Before Shipment China Floor Inspection Qualified Floor Factory Import Floor In China

ONLINE

ONLINE +86(551)82322038

+86(551)82322038 cfinspection@aliyun.com

cfinspection@aliyun.com