Mainly Specifications

Moisture Content: ≤8.0%

Density: ≥0.45g/cm3

Shrinkage: ≤0.30% in length, ≤0.40 in width

Expansion Rate: ≤0.20% in length, ≤0.30 in width

Thickness of Click Floor: 10.5/13 mm

Formaldehyde Emission: ≤1.50mg/L

Surface wear-resistant: ≤0.15g/100r

Residual area of indentation: ≤2%

Fire Rating: B2

Tensile Strength: ≥1.4MPa

2023-01-11 16:56:34

2022-09-06 10:34:35

2022-09-06 10:30:49

2023-02-15 10:13:32

CFI offers professional

FLOORING INSPECTION and FLOORING ADVICE!

Engineered Cork Click Flooring

The majority of cork used for flooring, as well as wine-bottle corks, is from the bark of the cork oak tree, or Quercus suber. The bark is hand-harvested every nine years, leaving a protective inner layer of bark that allows the tree to continue to grow and regenerate new bark.

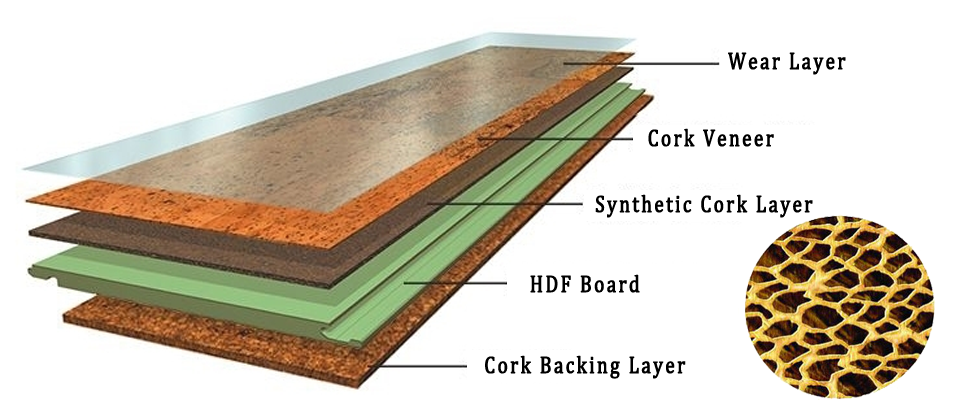

After drying for several months, the bark is boiled and ground up, then compressed using adhesive resins. This ground-up product can be cut and used as a final flooring piece. Some cork flooring planks include a high-density fiberboard within them as well.

Product Structure

Features

1. Vary style patterns. Cork click flooring comes in a wide variety of styles offering a range of design possibilities.There are as many as 40 different colors available and shapes ranging from squares and rectangles to hexagons.

2. Eco-friendly. According to the product processing, cork flooring do not consume wood resources, which is environment friendly comparing to hardwood flooring and engineered wood flooring.

3. Perfect soft feet feeling. Cork flooring contains about 50% air in its honeycomb structure, thus it has extremely high ductility and is as soft as sand beach.

4. Perfect skid resistance performance. The anti-skid factor of cork flooring is 6, which means it is skid resistant even there is oil stain on floor, and makes cork flooring is safe for elder and children.

5. Moisture resistance and fire resistance. Cork is quite stable that even been soaked in warm water for two hours under 25 degrees, its water absorption is only 0.012g/cm3. Moreover, cork will be carbonize and expand in fire to prevent air circulation, and its fire rating reaches B2 level.

6. Very suitable for geothermal system. Because of the grainy structure of cork flooring, which will spread heat away equally, it can be durable under temperature between -60℃ to 80℃.

QC Point

1. Check the backing material to reject cork flooring that with too little and dark grain, cause this kind of cork flooring uses the top of bark, which could weaken the effect of flexibility and silence.

2. Bonding strength test. Put a piece of cork in boiled water, the product will be unqualified if the sanding surface is rough and becomes uneven.

3. Quality of HDF is very important in cork click flooring. A good HDF that made from poplar and cypress could be 900kg/m3 in density.

Qualified Products

Our Advantages

CFI oversight will save cost by reducing defective products

- Control moisture to prevent splitting

- Supervise balance time to prevent warping

- Inspect glue used for excess formaldehyde preventing

- Avoid any business reputation damage caused by recall

- Ensure proper quality at every production stage

- Estimate possible production and shipment delays

- Optimize your quality control budget

- Improve your purchase efficiency

ONLINE

ONLINE +86(551)82322038

+86(551)82322038 cfinspection@aliyun.com

cfinspection@aliyun.com