2023-01-11 16:56:34

2022-09-06 10:34:35

2022-09-06 10:30:49

2023-02-15 10:13:32

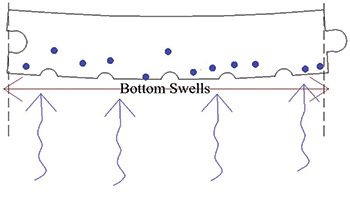

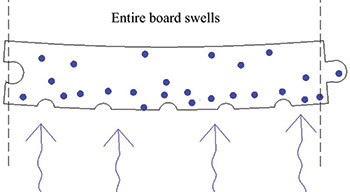

Exposed to moisture for an extended period of time, bamboo flooring products can absorb moisture and weaken. Because bamboo is grass, the grain runs the length of the board. Inferior or inappropriate bamboo selection, the use of bamboo that is either harvested too young or not properly dried can be prone to changes in temperature and humidity. This can lead to cupping, warping and swelling of the material.

1. Uneven distribution of floor moisture content

In the case of air drying, on the contrary, the board will bend like a slotted side.

▶

▶ ▶

▶

Solutions

1. In production:

When health balance, drying should not be too fast, drying kiln to keep the temperature uniform;

Try to make sure that both sides of the floor have the same texture

2. How to avoid before installation

Proper expansion joints reserved for paving

3. After installation

Because the weather humidity changes with the season, you can see if the floor will recover in a few months. If it is still tile, you can only replace the floor

ONLINE

ONLINE +86(551)82322038

+86(551)82322038 cfinspection@aliyun.com

cfinspection@aliyun.com